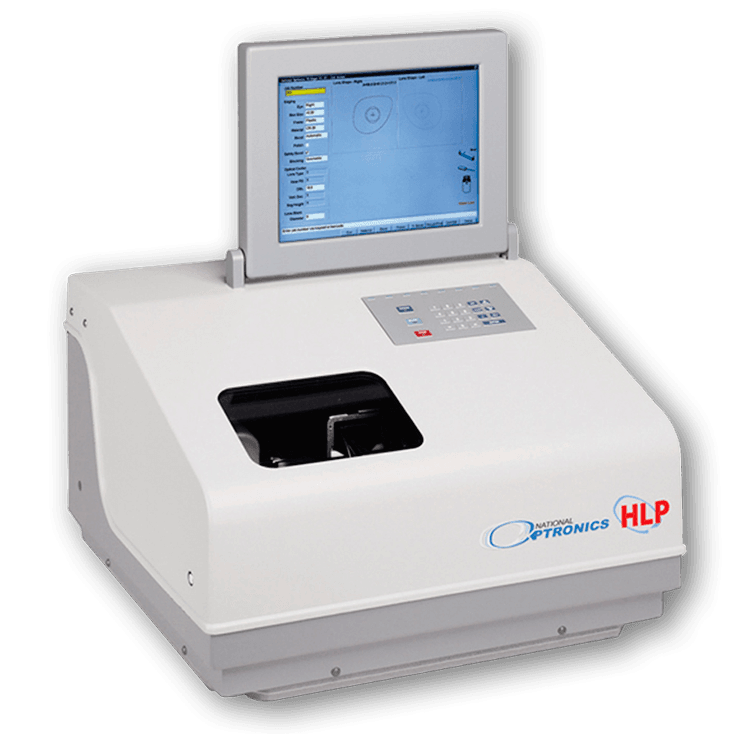

National Optronics Patternless Edger Repair

Professional patternless edger repair for all National Optronics models. Save on repair costs with our nationwide service and expert technicians.

Why Choose Our Patternless Edger Repair Service

We specialize in used National Optronics Edgers, Tracers, and Blockers. We have certified National Optronics technicians on staff who can answer any of your questions. We can refurbish your used optical laboratory equipment to make it look like new again. We rebuild motors, replace bearings, and recalibrate everything to make it run better than when it was new. National Optronics dry edgers are the backbone of a high quality and high-volume laboratory and last for years. If you need are in need of new optical edgers we try to keep refurbished optical edgers in stock, but they tend to go quickly.

Factory-Trained Technicians

Our technicians bring cross-industry expertise from computer hardware and laboratory sciences, ensuring expert diagnosis and repair.

Cost-Effective Solutions

Save significantly compared to manufacturer repairs without compromising on quality or warranty coverage.

Rapid Turnaround

Quick diagnosis and repair process to minimize your lab’s downtime. Emergency service available.

efurbished Optical Equipment

We specialize in used National Optronics Edgers, Tracers, and Blockers. We have certified National Optronics technicians on staff who can answer any of your questions. We can refurbish your used optical laboratory equipment to make it look like new again. We rebuild motors, replace bearings, and recalibrate everything to make it run better than when it was new. National Optronics dry edgers are the backbone of a high quality and high-volume laboratory and last for years. If you need are in need of new optical edgers we try to keep refurbished optical edgers in stock, but they tend to go quickly.

Our Refurbishing of Optical Edgers Include:

- Replace all bearings and/or belts that can be replaced

- Clean, paint or powder coat all parts depending on their wear

- All motors are re-built with new bearings and brushes

- Brushless motors are rewound

- Each machine is recalibrated

While Used National Optronics Edgers, Tracers, and Blockers are the staple of what we do, we have also worked extensively with Indo, Essilor Instruments, Edgers, Kappas, Gammas, Coburn, and Santinelli units. Most wet optical laboratory edgers tend to have tracer and blocker combination units or use standalone blockers. We have worked extensively with Speede Blockers and can calibrate your used optical blockers for you.

Optical Edger and Tracer Maintenance

Routine optical edger and tracer maintenance of your in-house optical finishing equipment is essential for maximizing the life of your equipment. While preventative service calls may still be needed every 6 months to 1 year for major updates and maintenance, we recommend the following self-maintenance to prolong the life of your equipment.

For Wet Edgers:

- Clean the filter and bucket daily or for every 20 pairs of lenses run through the unit.

- Rinse out the grinding chamber daily (with distilled water) and leave the door open for it to air dry, make sure to check behind the safety plate if your unit has one.

- Use a small toothbrush to clean off all of the grinding wheels and parts.

- Avoid using chemicals.

- Assign a staff member or manager to make sure the maintenance is performed on a regular basis, or keep a logbook or journal if more than one person uses the unit or units.

- For direct water edgers make sure the water and drain are connected properly daily and shut off the water between shifts.

For Dry Edgers:

- Vacuum out the internal parts of the edger daily.

- Make sure to check that the hose has proper suction and is free from debris.

- Empty out the bag and clean off the filter.

For Tracers:

- Make sure the probe is clean and free of debris and “frame cheese” between each trace.

- Vacuum out or use compressed air to ensure the tracer chamber is free of screws, wax, or other debris.

- Following these simple optical edger and tracer maintenance tips will ensure your equipment runs great in between regular service.

Our Advanced Patternless Edger Repair Process

Our comprehensive repair process ensures your National Optronics equipment is restored to optimal performance. Each step is performed by certified technicians using genuine parts and specialized testing equipment.

Initial Assessment

Comprehensive Diagnostic Evaluation

When your National Optronics edger arrives at our facility, our certified technicians begin a methodical diagnostic process that goes far beyond basic troubleshooting. Using specialized testing equipment and decades of experience, we perform a comprehensive evaluation of your entire system.

Our diagnostic process includes:

- Complete operational testing of all systems and functions

- Performance analysis of mechanical systems including drive mechanisms and cutting units

- Electronic systems diagnostic check using advanced testing equipment

- Motor and bearing condition assessment through vibration analysis

- Calibration verification across all measurement points

- Software and control system evaluation for proper function

This thorough initial assessment allows us to identify not just current issues, but potential future problems that could affect your equipment’s performance.

Components Inspection

Detailed Component Analysis

Following the initial assessment, we conduct a detailed component-by-component inspection of your edger. This critical phase helps us understand the full scope of work needed to restore your equipment to optimal performance.

Our certified technicians inspect:

- All bearings and belt systems for wear patterns and proper tension

- Motor condition including brush wear, commutator condition, and bearing noise

- Control board functionality through comprehensive electronic testing

- Calibration accuracy across all measurement points

- Vacuum system efficiency and filtration effectiveness

- Safety systems and emergency stop functions

Parts Replacement & Rebuilding

Premium Parts & Rebuild Process

Our commitment to quality means we never cut corners during the repair process. We use only genuine National Optronics parts and premium components to ensure reliability and longevity.

During this phase, we perform:

- Replacement of all worn bearings and belts with premium-grade components

- Complete motor rebuilding including new bearings and brushes

- Specialized rewinding of brushless motors when needed

- Professional powder coating or painting of worn surfaces

- Installation of genuine National Optronics parts

Calibration & Testing

Precision Calibration Process

Precise calibration is essential for accurate lens production. Our multi-point calibration process ensures your edger performs to the highest standards of accuracy and repeatability.

Our calibration process includes:

- Size verification system calibration using certified test equipment

- Precision axis alignment adjustment and verification

- Probe system calibration for accurate frame tracing

- Cutting pressure optimization for different lens materials

- Feed rate calibration for optimal edge quality

- Multiple test cuts with various lens materials

National Optronics Models We Service

- 7E Patternless Edger

- 6E Patternless Edger

- 5E Patternless Edger

- Legacy Models

- Control Boards

- Drive Systems

- Specialized Components

While Used National Optronics Edgers, Tracers, and Blockers are the staple of what we do, we have also worked extensively with Indo, Essilor Instruments, Edgers, Kappas, Gammas, Coburn, and Santinelli units. Most wet optical laboratory edgers tend to have tracer and blocker combination units or use standalone blockers. We have worked extensively with Speede Blockers and can calibrate your used optical blockers for you.

What is your typical turnaround time?

Standard repairs are typically completed within 3-5 business days. Emergency service is available when needed.

Do you provide warranty coverage?

Yes, all repairs include a comprehensive warranty covering both parts and labor.

How do your costs compare to manufacturer service?

Our repair services typically cost 40-60% less than manufacturer pricing while maintaining the same quality standards.

What parts do you use for repairs?

We use genuine National Optronics parts to ensure reliability and proper function.

Let OptitechUSA Answer Your Edger Questions

Frequently Asked Questions

Ready to Get Your Patternless Edger Repaired?

Contact us today for pricing and availability. Same-day quotes and priority scheduling available.